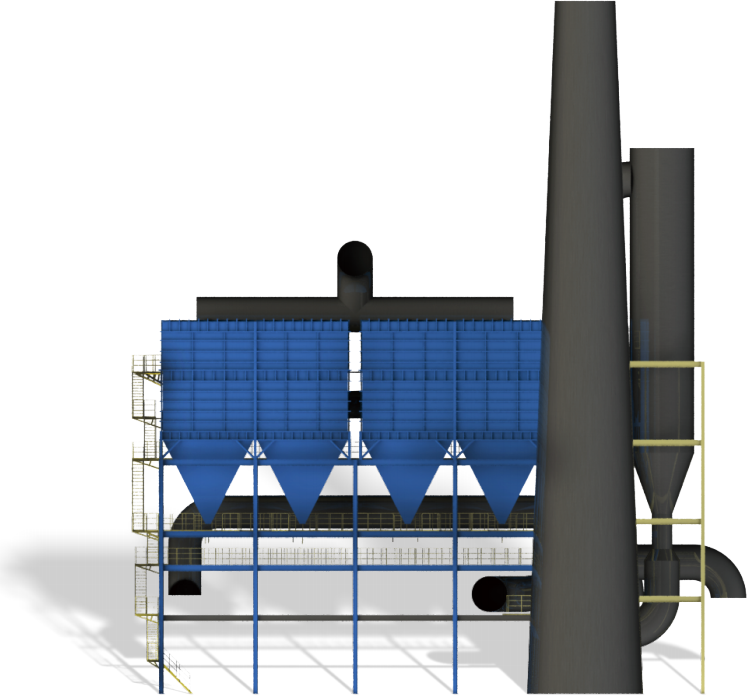

Dry desulfurization and denitrification high-temperature ceramic dust removal equipment

Dry desulfurization and denitrification high-temperature ceramic dust removal equipment is a device that integrates desulfurization, denitrification, and dust removal functions

Working principle: High temperature flue gas filtration technology is used to filter particulate matter in flue gas through ceramic filter elements or ceramic membranes, while removing pollutants such as sulfur oxides (SOx) and nitrogen oxides (NOx).

High temperature adaptability: capable of operating at high temperatures and suitable for exhaust gas treatment in various industrial furnaces and kilns;

Efficient dust removal: With a high filtration efficiency of over 99.9%, the emission concentration is below 2mg/m ³;

Simultaneously desulfurization and denitrification: The removal efficiency of SOx and NOx is good, with a nitrogen oxide removal rate of over 95% and a dioxin removal rate of over 99%;

Good chemical stability: Ceramic materials have the characteristics of acid and alkali resistance and other chemical corrosion

Dry jet desulfurization: The dry jet method can be used to effectively remove sulfur oxides;

Waste heat recovery: Due to the small temperature drop, waste heat recovery can be carried out;

Small footprint: The integrated design reduces the equipment footprint.

Application scope: Widely used in glass furnace industrial waste gas treatment, garbage incineration, metallurgical industry, precious metal recycling, chemical filtration, ceramic industry

Thermal power plants, cement industry and other fields

A daily glass kiln outlet emits flue gas at around 350 ℃. Firstly, dry desulfurization is carried out, and the desulfurized flue gas enters the dust and nitrate integrated equipment. The dust containing flue gas is treated by ceramic filter for dust removal and denitrification, and the purified flue gas is then recovered by energy-saving devices. Finally, it is introduced into the chimney by a fan and discharged into the atmosphere.

Project process: Glass furnace - Dry desulfurization - Dust and nitrate integrated equipment - (energy-saving device) - Fan - Chimney

Address: No. 260, Building 6, Fuling Road, Shuangliu Park, Jiaolong Industrial Port, Chengdu

Address: No. 260, Building 6, Fuling Road, Shuangliu Park, Jiaolong Industrial Port, Chengdu Phone: 028-85880837

Phone: 028-85880837 Email: ts.2017@sctshb.com

Email: ts.2017@sctshb.com